Starting a construction project without an excavator is like setting sail without a compass—it's possible, but not advisable. These powerful machines are essential for digging foundations, trenches, and moving heavy materials. However, their effectiveness varies depending on the job, which is why different types of excavators have been developed to suit specific tasks and environments.

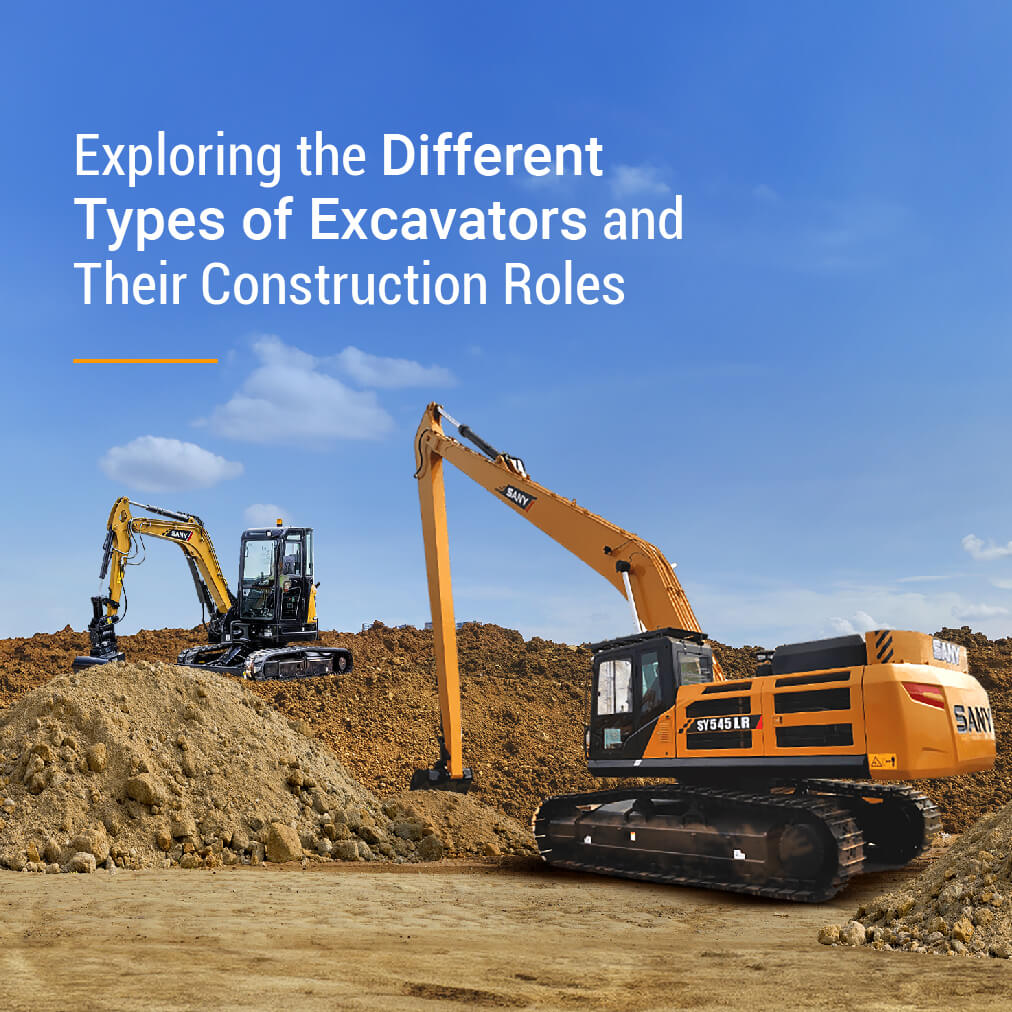

From compact mini excavators that work well in tight spaces to massive hydraulic excavators used for large-scale projects, each type has its own strengths. The wide range of attachments available also helps expand the versatility of these machines, allowing them to handle multiple tasks efficiently. In this blog, we’ll explore the various types of excavators and the attachments that make them so adaptable.

Types of Excavator Machines

Here are some of the most common excavator types found on construction sites:

Wheeled Excavators

Wheeled excavators are known for their mobility and speed, making them ideal for urban construction and road projects. They can move quickly over paved surfaces and uneven ground, offering great flexibility. Their rotating platforms and buckets allow them to dig, lift, and move materials with ease.

- Application: Perfect for road construction, city development, and any project requiring fast movement between locations.

Long-Reach Excavators

Long-reach excavators feature extended booms and arms, enabling them to reach deep into trenches or high up into structures. They are commonly used in dredging, demolition, and bridge construction where traditional excavators might struggle to access certain areas.

- Application: Great for deep excavation, waterway maintenance, and demolition projects in hard-to-reach places.

Mini Excavators

Mini excavators are smaller and more maneuverable, making them perfect for tight spaces such as parking lots, indoor areas, or crowded urban sites. Many models come with zero tail-swing designs, allowing them to turn without hitting nearby obstacles.

- Application: Ideal for utility work, landscaping, and small residential projects where space is limited.

Small Excavators

Small excavators are slightly larger than mini models but still compact enough for use in confined areas. They offer a good balance of power and portability, making them suitable for a variety of medium-sized jobs.

- Application: Used in residential construction, utility installations, and landscaping tasks.

Medium Excavators

Medium excavators are versatile machines that can handle both light and heavy-duty tasks. They are often used in building construction, infrastructure development, and general earthmoving operations due to their balanced performance and durability.

- Application: Suitable for commercial construction, roadworks, and general excavation needs.

Large Excavators

Large excavators are built for heavy-duty applications such as mining, large-scale earthmoving, and major infrastructure projects. These machines are powerful and durable, capable of handling the toughest conditions on the job site.

- Application: Ideal for mining operations, large construction projects, and deep excavation tasks.

Different Types of Excavator Attachments

Excavator attachments greatly enhance the functionality of these machines, allowing them to perform a wide range of tasks beyond basic digging. Here are some of the most commonly used attachments:

Rock Breaker

A rock breaker is an attachment that delivers powerful impacts to break through hard materials like stone or concrete. It’s particularly useful in demolition and site preparation projects where breaking up material is necessary.

Coupler

Couplers allow for quick and easy swapping of tools without the need for additional labor. This makes them highly efficient for changing between different tasks on the same job site, improving productivity and reducing downtime.

Pile Driver

A pile driver is used to drive piles into the ground, providing strong foundation support for buildings or bridges. It plays a critical role in projects where deep and stable foundations are required.

To Conclude

Understanding the different types of excavators and their specific uses is crucial for optimizing construction efficiency. Choosing the right machine and attachments ensures that each project runs smoothly and effectively.

As a leading supplier of construction equipment, Sany India offers a wide range of excavators designed to meet the demands of modern construction. From compact mini models to large-scale machines, our excavators combine advanced technology with durability to deliver reliable performance. With a focus on quality and customer satisfaction, Sany India ensures that every machine meets the highest standards of productivity and reliability. Choose Sany India for top-tier excavators that deliver exceptional results on every job site.

Excavator Final Drive

â… . Strong power source

â…¡. Complete product models

â…¢. Superior quality assurance

1.Quality control

2.Production process

Our products

Final Drive,Excavators Final Drive,Excavator Final Drive

XINGTAI ZHONGWEI ZHUOTE HYDRAULIC TECHNOLOGY CO.,LTD , https://www.zwzhtehydraulic.com