Starting a construction project without an excavator is like setting sail without a compass—it’s possible, but not advisable. These powerful machines are essential for tasks such as digging foundations, trenches, and loading heavy materials. However, their performance varies depending on the job, which is why different types of excavators have been developed to suit specific needs and environments.

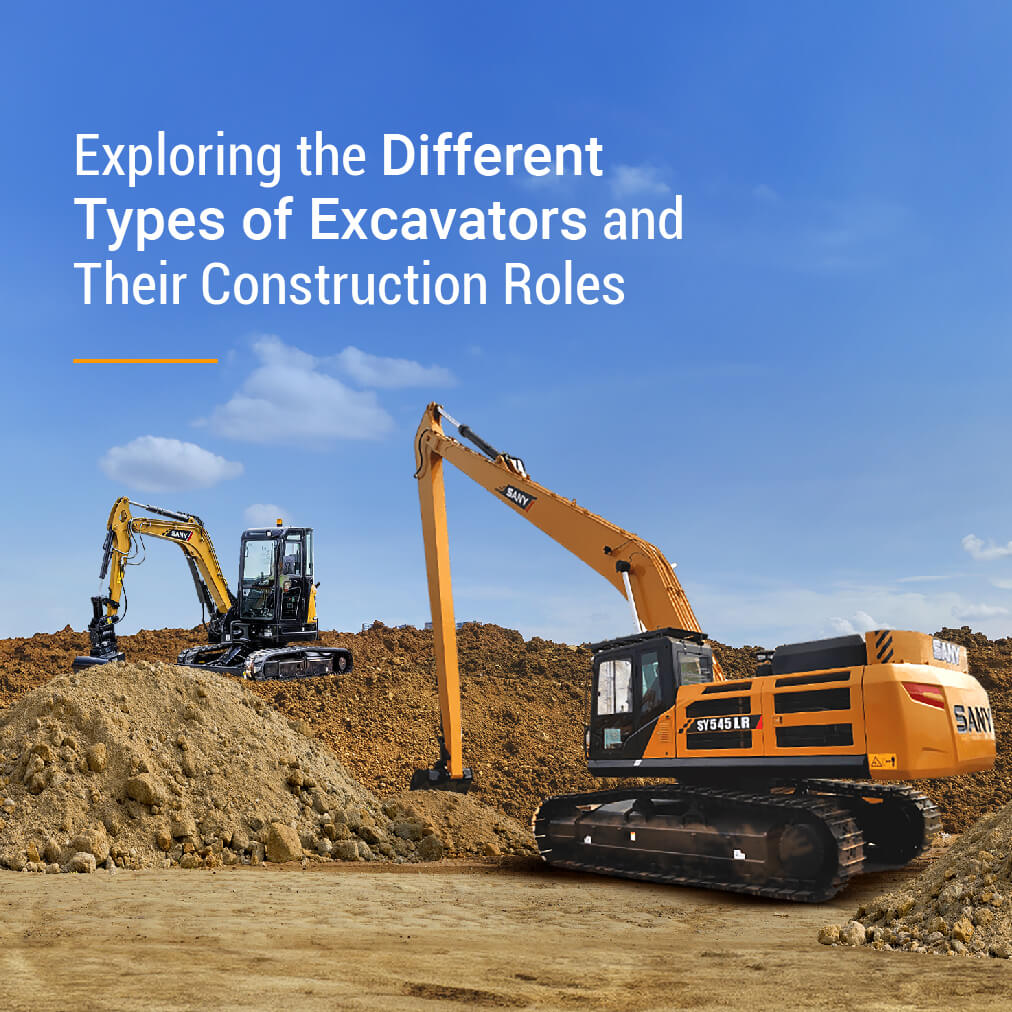

From compact mini excavators ideal for tight spaces to massive hydraulic models used in large-scale projects, each type of excavator brings unique advantages to the table. The versatility of these machines is further enhanced by a wide range of attachments, allowing them to tackle various tasks with precision and efficiency. In this blog, we’ll take a closer look at the different types of excavators and the attachments that make them so adaptable.

Types of Excavator Machines

Here are some of the most commonly used excavator types in construction:

Wheeled Excavators

Wheeled excavators are known for their mobility and speed, making them ideal for road construction and urban development. They can easily navigate paved surfaces and uneven terrain thanks to their rotating platforms, arms, and buckets. Their ability to move quickly from one site to another makes them a popular choice for projects that require frequent repositioning.

- Application: Best suited for roadwork, city projects, and jobs where quick movement is needed.

Long-Reach Excavators

Long-reach excavators feature extended booms and arms, allowing them to dig deep or reach high places. They are often used in waterway maintenance, bridge construction, and demolition work. These machines maintain stability even when working at great distances, making them essential for challenging environments.

- Application: Used for deep digging, dredging, and demolition in hard-to-reach areas.

Mini Excavators

Mini excavators are smaller and lighter, designed to minimize ground damage and operate in tight spaces. Many models come with zero or reduced tail-swing configurations, allowing them to turn in small areas without hitting nearby structures. This makes them perfect for urban settings, indoor work, and landscaping projects.

- Application: Ideal for parking lots, residential areas, and other confined spaces.

Small Excavators

Small excavators offer a good balance between power and size, making them suitable for a variety of small to medium-sized projects. They are easy to transport and operate, and they perform well in tight or restricted areas.

- Application: Perfect for utility work, landscaping, and home improvement projects.

Medium Excavators

Medium excavators are versatile machines that can handle both light and heavy tasks. They are widely used in general construction, infrastructure development, and excavation projects where more power than a small machine provides is required.

- Application: Suitable for building construction, roadworks, and general earthmoving.

Large Excavators

Large excavators are built for heavy-duty tasks, offering immense power and reach. They are essential for mining operations, major infrastructure projects, and large-scale earthmoving. These machines are designed to withstand tough conditions and deliver consistent performance over long periods.

- Application: Used in mining, large construction sites, and major civil engineering projects.

Different Types of Excavator Attachments

Excavator attachments significantly expand the capabilities of these machines, enabling them to perform a wide range of tasks beyond basic digging. Here are some of the most common attachments used in construction:

Rock Breaker

A rock breaker is an attachment that delivers powerful impacts to break through hard materials like concrete and stone. It’s commonly used in demolition and site preparation, helping to clear obstacles efficiently and safely.

Coupler

Couplers allow for quick tool changes without the need for additional labor. This makes it easier to switch between different attachments, improving productivity and reducing downtime on the job site.

Pile Driver

A pile driver is used to drive piles into the ground, providing a stable foundation for buildings or structures. It's especially useful in areas with soft soil or where deep foundations are required.

To Conclude

Understanding the different types of excavators and their specialized functions is key to maximizing efficiency on any construction site. By choosing the right machine and attachments, contractors can improve productivity, reduce costs, and complete projects faster and more accurately.

As a leading supplier of construction equipment, we provide a wide range of high-quality excavators tailored to meet the needs of every project. From compact mini excavators to heavy-duty models, our machines are built to last and perform under the toughest conditions. With a focus on innovation, reliability, and customer satisfaction, Sany India ensures that every excavator delivers exceptional performance and value. Choose Sany India for superior construction solutions and unmatched productivity on your next project.

I. Introduction to ZHTE HYDRAULIC Excavator Excavator Hydraulic Pump

II. Product Introduction and Categories

III. Production Process

V. Enterprise Qualification

Our products

Hydraulic Excavator Pump,Hydraulic Pump Mini Excavator,Excavator Parts Hydraulic Pump,Main Hydraulic Pump

XINGTAI ZHONGWEI ZHUOTE HYDRAULIC TECHNOLOGY CO.,LTD , https://www.zwzhtehydraulic.com