Specification:

Max. mold closing stroke:150mmPressing injection stroke: 50mm

Hydraulic system working pressure: 10~25MPa

Hydraulic motor power: 7.5kw

Oil tank capacity: 350L

Power: 380V 50Hz

Rotor stack length: 16-100mm

Rotor OD: 40-100mm

Pitch time ≤18~24s

Change-over time: 20mins

Upper Presser operation pressure: 40T

Bottom presser operation pressure: 15T

Machine weight: 3200kg

Â

Machine features:

Automatic get aluminium melt liquid, automatic loading and unloading the rotor.

Rotor loading: automatic pneumatic circularly pick up.

Get aluminium melting liquid: servo motor control the mechanical arm, control the liquid volume through human-machine interface.

Automatic cut the waste material, automatic recycle the cut wasted material and convey it to the furnace by the conveyor.

Automatic feed mold releasing agent, the feeding time and times can be set.

There is water cooling channel, helpful for reducing the mold temperature effectively.

Setting on touch screen: forward and backward speed, stroke, swing angle of the mechanical arm, loading speed,etc.

Machine will alarm and stop working if out of material.

Failure will be automatic displayed and machine will alarm.

One person can take care of more than one machine.

Â

Rotor sample after die casting

Â

Specification:

Max. mold closing stroke:150mmPressing injection stroke: 50mm

Hydraulic system working pressure: 10~25MPa

Hydraulic motor power: 7.5kw

Oil tank capacity: 350L

Power: 380V 50Hz

Rotor stack length: 16-100mm

Rotor OD: 40-100mm

Pitch time ≤18~24s

Change-over time: 20mins

Upper Presser operation pressure: 40T

Bottom presser operation pressure: 15T

Machine weight: 3200kg

Â

Machine features:

Automatic get aluminium melt liquid, automatic loading and unloading the rotor.

Rotor loading: automatic pneumatic circularly pick up.

Get aluminium melting liquid: servo motor control the mechanical arm, control the liquid volume through human-machine interface.

Automatic cut the waste material, automatic recycle the cut wasted material and convey it to the furnace by the conveyor.

Automatic feed mold releasing agent, the feeding time and times can be set.

There is water cooling channel, helpful for reducing the mold temperature effectively.

Setting on touch screen: forward and backward speed, stroke, swing angle of the mechanical arm, loading speed,etc.

Machine will alarm and stop working if out of material.

Failure will be automatic displayed and machine will alarm.

One person can take care of more than one machine.

Â

Rotor sample after die casting

Â

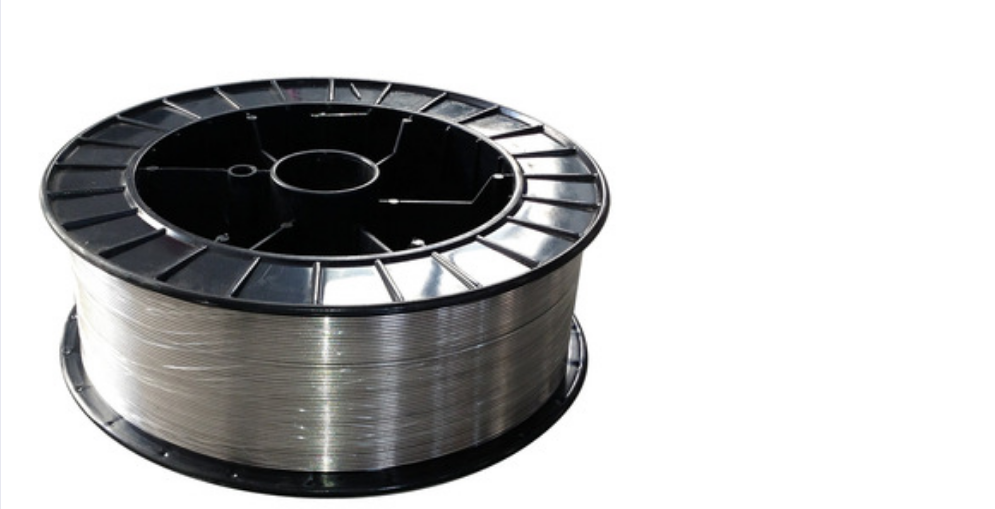

Metals, alloys and composite powders commonly used in thermal spray hardfacing technology and coating service. These unique powders are instantly heated by thermal spraying (welding) methods such as high temperature flame or explosive flame, and are sprayed and deposited on the cold or hot workpiece surface with high-speed heat flow in a molten or semi-melted state to form a surface Reinforcing layer, in order to improve the wear resistance, corrosion resistance, heat resistance, oxidation resistance or repair of external dimensions of the workpiece surface. XTC produces WC, CrC, Oxide Ceramic, Boride Powder, Metal Alloy Powder, Pure Metal and Spray Wire, etc. product. For HVOF/HVAF/plasma/Flame spray coating and applications. Meet the wear and corrosion resistance requirements of different surfaces.

WC, CrC oxide ceramic powder and boride products are excellent in wear resistance and high temperature corrosion resistance. Taking WC products as an example, the hardness can reach HV1300-1500, and the temperature of CrC products can reach 800 degrees Celsius.

Metal alloy powder, Pure Metal and Spray Wire products have more applications in glass mold, steel and machinery industries. And XTC products are now become more and more popular in Metal spray coating and thermal spray coating industry.

Coating Service,Metal Spray Coating,Flame Spray Coating,Thermal Spray Coating

Luoyang Golden Egret Geotools Co., Ltd. , https://www.xtcmetalpowder.com