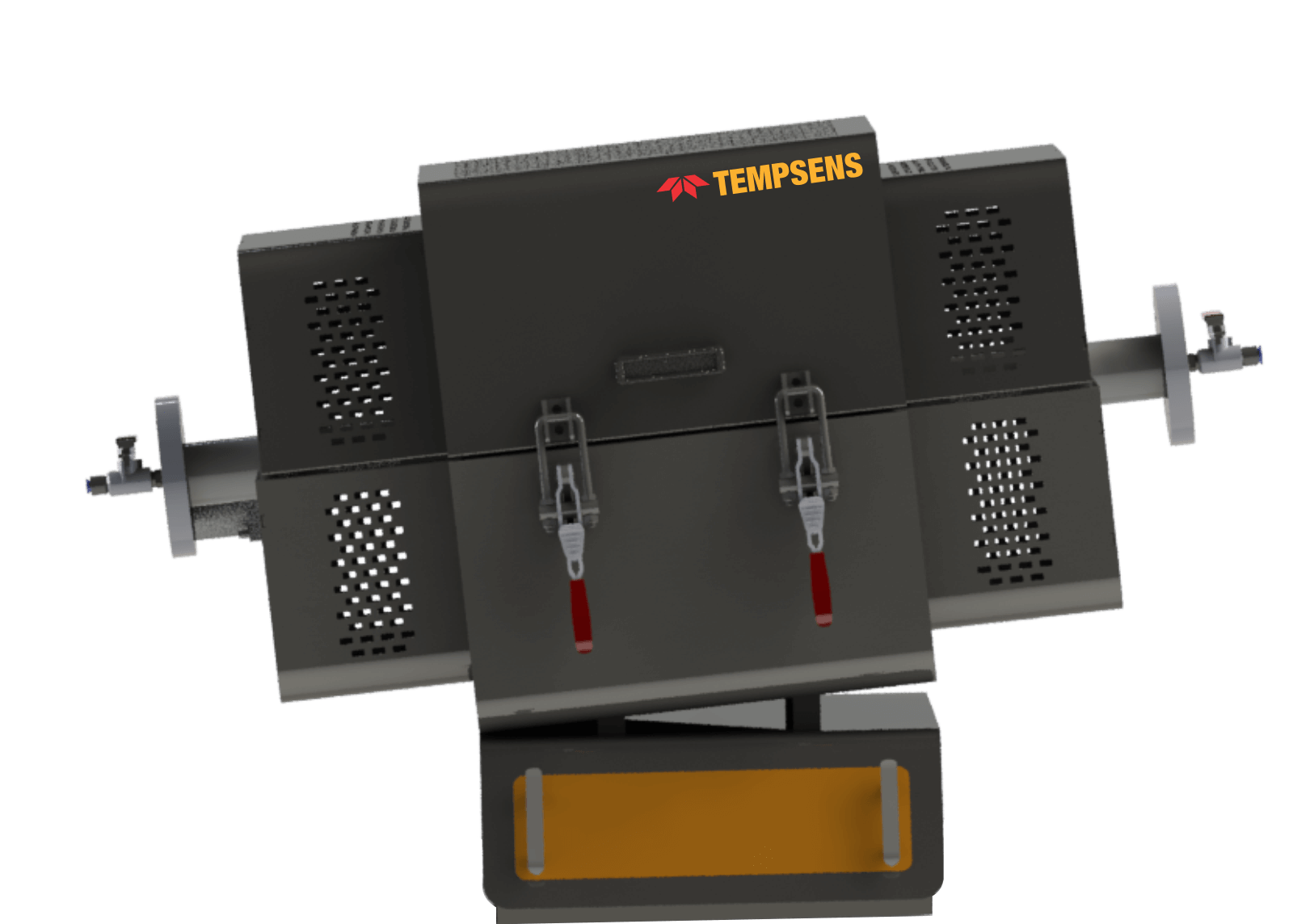

- Low RPM range (1–20 RPM): Ideal for delicate materials, ensuring even heat exposure and preventing clumping. This also allows for precise control over material residence time.

- Tilt angle (6–15°): Adjusts material flow by altering gravitational effects, optimizing processing efficiency.

- Gas purging & vacuum atmosphere: Offers versatility for different process requirements, including sintering and annealing.

- Continuous & batch operation: Supports both small-scale and large-scale production, enhancing scalability.

- Maximum temperature (1200°C): Suitable for a wide range of industrial applications, such as carbonization and ceramic sintering.

- Split mechanism for easy loading: Reduces downtime and improves operational efficiency during frequent material changes.

- Tube material: Available in quartz or alumina, depending on the application requirements.

- Scraper bars for proper mixing: Ensures even material distribution and prevents sticking to the tube walls.

Tailorization Offered by Tempsens

- Multiple temperature zones

- Customizable holding time based on tilt angle

- Scraper bars inside the work tube for improved mixing

- Input hopper with screw feeder

- Gas purging and vacuum system

- Programmable PID controller with RS-232/RS-485/Ethernet and data logging software

Recent Development: Tempsens Rotary Tube Furnace for Carbon Activation

Tempsens has developed an advanced rotary tube furnace specifically for the carbon activation process. Designed for precision and efficiency, this furnace transforms raw carbon-based materials—such as coconut shells or coal—into high-quality activated carbon. The process involves carbonization followed by activation under an Argon atmosphere at temperatures up to 800°C. The continuous rotation ensures even heat and activating agent exposure, resulting in enhanced porosity and surface area, which are critical for high adsorption capacity. This technology offers reliable, scalable, and energy-efficient solutions for industrial carbon activation needs.Applications

- Powder processing: Calcination, Sintering, Drying

- Material Synthesis: Ceramics, Advanced Materials, Nanomaterials

- Thermal Treatment of Chemicals: Catalysts, Reactions in Controlled Atmospheres

- Carbon activation and carbonization

- Metallurgical Processes

- Pharmaceutical powders

Advantages of Using Tempsens Rotary Tube Tilt Furnace

- Enhanced Material Mixing: The rotating tube improves heat transfer and prevents clumping.

- Improved Heat Efficiency: Uniform thermal distribution leads to lower energy consumption.

- Ease of Discharge: The tilting function facilitates smooth material removal without manual intervention.

- Customization Options: Flexible design to suit specific process requirements, including tube material and length.

Sponge Fiber Compress Machine,Sponge Fiber Baling Press Machine,Sponge Fiber Baler Press Machine,Sponge Fiber Baler Machine

Nantong Sika Machinery Co., Ltd. , https://www.sikamachinery.com