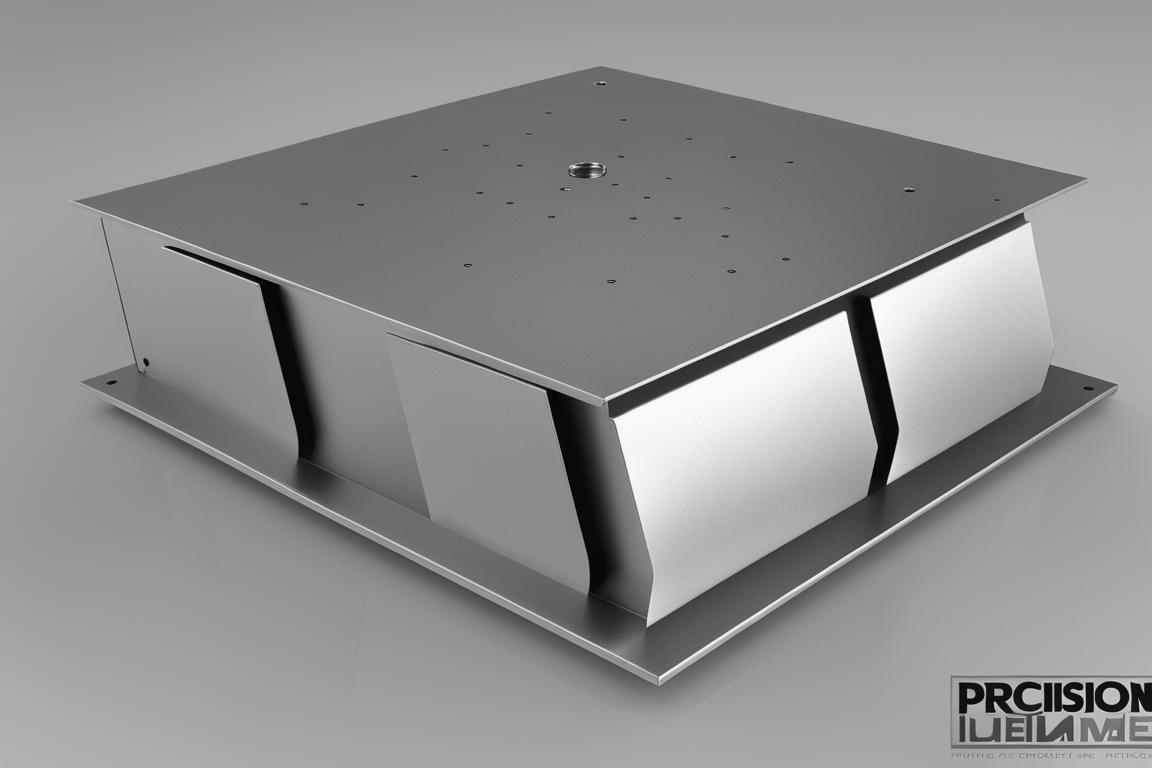

Discover the World of Custom Sheet Metal Boxes

- Understanding the importance of custom sheet metal boxes across different industries.

- Exploring the advantages, design process, material choices, and fabrication methods for these boxes.

- Guidelines on selecting the right manufacturer and maintaining your custom sheet metal boxes for long-term use.

Are you curious about how custom sheet metal boxes can transform your business needs? In today’s fast-paced world, the demand for custom sheet metal boxes is growing rapidly due to their adaptability and precision. These boxes are not just generic storage solutions; they are specifically designed to meet unique requirements in terms of size, shape, and functionality. From electronics to aerospace and automotive sectors, custom sheet metal boxes play a crucial role in ensuring safe transportation, efficient storage, and reliable protection of sensitive components.

Advantages of Custom Sheet Metal Boxes

Custom sheet metal boxes offer a range of benefits that make them stand out from standard, mass-produced options. One of the key advantages is precision. By tailoring the dimensions and features, businesses can optimize space and ensure a perfect fit for their specific applications. The durability of sheet metal also makes these boxes ideal for protecting valuable items against damage. Additionally, the customizable aesthetics allow for branding and professional finishes that enhance the overall look of the product.

Design and Engineering Process

The creation of custom sheet metal boxes involves a detailed and structured design process. Engineers often begin with CAD (Computer-Aided Design), which allows for precise 3D modeling and visualization of the final product. This step is essential for identifying potential issues early on and making necessary adjustments before moving into production. Prototyping is also an important phase, as it enables testing and refinement of the box’s structure and function.

CAD Design in Custom Sheet Metal Boxes

CAD software plays a vital role in designing custom sheet metal boxes by enabling accurate measurements and visual representations. It helps engineers anticipate challenges and make modifications at the design stage, which saves time and resources during the actual manufacturing process.

Choosing the Right Materials

Selecting the appropriate sheet metal material is essential for ensuring the performance and longevity of the box. Common choices include aluminum, stainless steel, and carbon steel, each offering unique properties. For instance, aluminum is lightweight and resistant to corrosion, making it ideal for a wide range of applications. Stainless steel, on the other hand, is known for its strength and aesthetic appeal, making it suitable for high-end or industrial uses.

| Fabrication Technique | Description |

|---|---|

| Cutting | Shaping metal sheets according to design specifications using laser cutting or shearing methods |

| Bending | Forming the structural components of the box through bending techniques |

| Welding | Joining individual components together to create a sturdy structure using TIG or MIG welding |

| Finishing | Enhancing the appearance and durability of the box through treatments like powder coating or anodizing |

Fabrication Techniques for Custom Sheet Metal Boxes

Creating custom sheet metal boxes requires a combination of advanced fabrication techniques. Cutting processes such as laser cutting or shearing are used to shape the metal sheets precisely. Bending is then applied to form the box’s structure, while welding ensures strong and durable joints. Finally, finishing treatments like powder coating or anodizing improve both the appearance and resistance to wear and tear.

Welding in Custom Sheet Metal Boxes

Welding is a critical part of the fabrication process, especially when joining multiple components of the box. Techniques like TIG and MIG welding are commonly used to create strong, clean welds that enhance the box's structural integrity and longevity.

Precision and Quality Control

Maintaining precision throughout the manufacturing process is essential for producing high-quality custom sheet metal boxes. Rigorous quality control measures help identify and correct any deviations from the original design. This ensures that every product meets the highest standards of performance and reliability, giving clients peace of mind and confidence in their purchase.

Customization Options for Sheet Metal Boxes

One of the biggest advantages of custom sheet metal boxes is the ability to tailor them to specific needs. Clients can choose from a variety of customization options, including size, shape, color, and finish. Additional features like engraved logos or labels can be added to enhance brand visibility and identification. This level of personalization makes custom sheet metal boxes a versatile solution for a wide range of industries.

Real-World Applications of Custom Sheet Metal Boxes

Custom sheet metal boxes are widely used across various industries, showcasing their versatility and practicality. Here are some examples:

- Electronics Industry: Custom boxes are used to protect delicate components, ensuring safe storage and transport.

- Medical Equipment: Designed to meet strict hygiene and safety standards, these boxes are essential for transporting medical devices.

- Automotive Sector: Custom sheet metal boxes help organize and store parts efficiently, improving inventory management.

Current Trends in Custom Sheet Metal Box Fabrication

The industry is constantly evolving, driven by technological advancements and changing market demands. Digitalization has improved design accuracy and reduced production time, while sustainable practices such as recycling and waste reduction are becoming more common. Automation is also playing a significant role in increasing efficiency and ensuring consistent quality in the manufacturing process.

Selecting the Right Fabrication Partner

Choosing the right partner for custom sheet metal box projects is crucial for success. Look for a company with proven expertise in sheet metal fabrication, a track record of handling complex designs, and positive customer reviews. A reliable partner will not only deliver quality products but also provide support throughout the entire project lifecycle.

Maintaining Your Custom Sheet Metal Boxes

To ensure your custom sheet metal boxes last longer, follow proper maintenance guidelines. Regular cleaning and inspections can prevent rust and damage. Avoid exposing the boxes to harsh chemicals or extreme temperatures, and lubricate moving parts like hinges and latches to maintain smooth operation. With proper care, these boxes can serve you reliably for many years.

The Future of Custom Sheet Metal Box Fabrication

The future of custom sheet metal box manufacturing looks promising, with innovations like 3D printing and smart integration opening up new possibilities. Sustainability is also a growing focus, with more companies adopting eco-friendly materials and energy-efficient processes. As technology continues to advance, the industry will keep evolving to meet the changing needs of businesses worldwide.

Frequently Asked Questions

Who can benefit from custom sheet metal boxes?

Businesses in need of precise and durable storage solutions.

What makes custom sheet metal boxes unique?

They are tailored to specific dimensions and designs.

How are custom sheet metal boxes fabricated?

They are crafted using precision sheet metal fabrication techniques.

Who can I contact for custom sheet metal box orders?

You can reach out to experienced sheet metal fabrication companies.

What if I need a custom sheet metal box quickly?

Some fabrication companies offer expedited services for urgent orders.

How durable are custom sheet metal boxes?

Custom sheet metal boxes are incredibly sturdy and long-lasting.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Businesses in need of precise and durable storage solutions."}}, {"@type": "Question", "name": "What makes custom sheet metal boxes unique?", "acceptedAnswer": {"@type": "Answer", "text": "They are tailored to specific dimensions and designs."}}, {"@type": "Question", "name": "How are custom sheet metal boxes fabricated?", "acceptedAnswer": {"@type": "Answer", "text": "They are crafted using precision sheet metal fabrication techniques."}}, {"@type": "Question", "name": "Who can I contact for custom sheet metal box orders?", "acceptedAnswer": {"@type": "Answer", "text": "You can reach out to experienced sheet metal fabrication companies."}}, {"@type": "Question", "name": "What if I need a custom sheet metal box quickly?", "acceptedAnswer": {"@type": "Answer", "text": "Some fabrication companies offer expedited services for urgent orders."}}, {"@type": "Question", "name": "How durable are custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Custom sheet metal boxes are incredibly sturdy and long-lasting."}}]}Ø The pipe is widely used for water drainage and sewage in many fields, such as municipal construction, residential districts, highways and bridges, etc.

Ø The first extruder produce rectangular pipe into winding forming machine, the second extruder produce plastic bar, then the plastic bar is pressed on the rectangular pipe and winding pipe comes out.

Ø Main motor uese the famous brands (Siemens/WN/WEG).

Ø Gearbox from the well-known domestic manufacturers (GuoMao/ShuGuang).

Ø Main extruder and Haul-off Machine use the imported invesor (ABB/Yaskawa).

Ø Electrical components are all imported brands (Simens/Schneider)

Ø PLC is optional for control system (Simens/Delta/Fatek)

Pipe Extrusion Machine For Plastic,Pp Pipe Extruder Machine,Pe Pipe Extruder Production Line,Pipe Extrusion For Pvc Household

RECTO MACHINERY CO., LTD RICO (NINGBO) IMP & EXP CO., LTD , https://www.recto-rico.com