When it comes to pump maintenance, you often need to use conversions to get the right answers for an accurate pump assessment. Have you ever found yourself searching online for formulas to fill in the gaps? This is exactly why our engineers created a "toolbox" of common pump conversions—covering everything from specific gravity to pressure and power. We’ve worked through some of the most frequently used conversions so you can understand how they work and apply them on your own. With a bit of simple math, you’ll be ordering parts and solving pump issues faster than ever before.

[insert table image]

Section 1: How to Calculate Pressure Conversions

How to Convert PSI to TDH

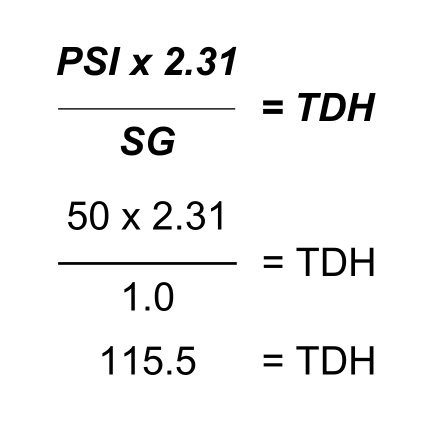

Let’s say you need a pump to provide an extra 50 PSI to your system. However, your pump curve only shows pressure in Total Dynamic Head (TDH). How do you convert PSI to TDH? Using the standard pressure formula, we've calculated this conversion using water as the fluid, which has a specific gravity (SG) of 1.0.

Start by multiplying your PSI value (50) by the constant 2.31. Then divide that result by the specific gravity of the fluid (1.0). The calculation gives you 115.5 TDH, meaning you should look for a pump that can deliver 115.5 TDH at your required flow rate.

How to Convert TDH to PSI

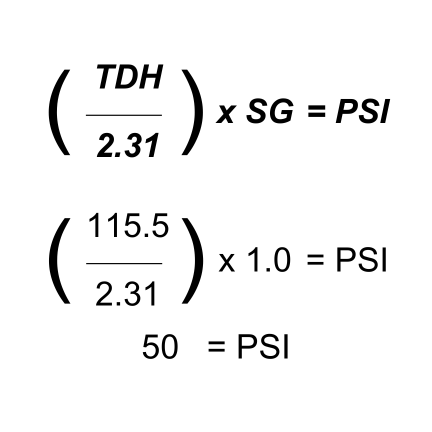

You can also reverse the formula to convert TDH back to PSI. This is helpful when checking what pressure your pump will deliver based on its curve, which is typically shown in TDH units.

Using the earlier example with 115.5 TDH, divide that number by 2.31 and then multiply by the fluid's specific gravity (1.0). The result is 50 PSI, confirming the pressure your pump will provide.

Section 2: How to Calculate Horsepower Conversion

How to Calculate Hydraulic (Liquid) Horsepower

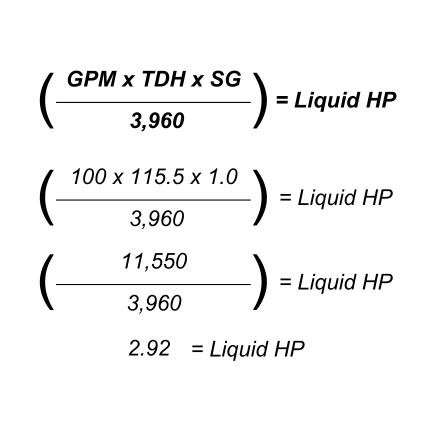

If you want to determine the horsepower generated by your fluid at a given flow and pressure, you need to calculate the Hydraulic Horsepower (LHP). To do this, you'll need the gallons per minute (GPM), total dynamic head (TDH), and the specific gravity (SG) of the fluid.

In this example, GPM is 100, TDH is 115.5, and SG is 1.0 (for water). Multiply GPM × TDH × SG, then divide by the constant 3,960. The result is 2.92 LHP, which tells you the power your fluid is generating.

How to Calculate Brake Horsepower

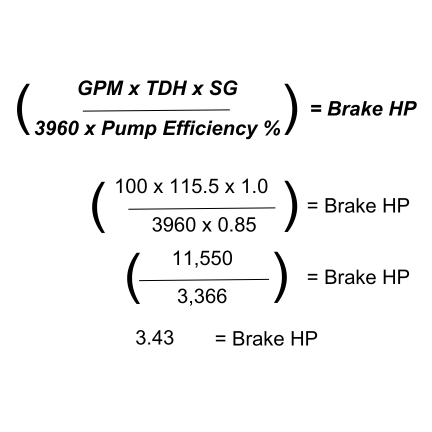

To find the input power delivered by the motor to the pump, you need to calculate the Brake Horsepower (BHP). For this, you’ll need GPM, TDH, SG, and the pump’s efficiency percentage (usually found on the performance curve).

In our example, GPM is 100, TDH is 115.5, SG is 1.0, and the pump’s efficiency is 85%. Multiply GPM × TDH × SG, then divide by the product of 3,960 and the efficiency (0.85). The result is 3.43 BHP, which represents the actual power needed by the motor.

(Tip: The difference between BHP and LHP is due to pump efficiency. You can also divide LHP by the efficiency to get BHP.)

If you’d like help with more calculations or different scenarios, feel free to reach out—we’re always happy to assist!

TALK WITH AN EXPERTOur engineers are dedicated to meeting your pump needs every day. Whether it's solving complex problems or ensuring your repaired or custom pumps fit perfectly into your system, we're here to help. Double-check your numbers with one of our experts today. |

Contact Us |

changan deepal S07,changan shenlan S7,changan deepal sl03,changan deepal price

Henan Wangdao Automobile Service Co., Ltd. , https://www.wangdaocars.com